Flynt and Kallenberger engineer, Justin Roush P.E., knew from previous experience that the non-ducted VRV systems would have trouble meeting ASHRAE Standard 62 (Ventilation for Acceptable Indoor Air Quality) while maintaining a comfortable environment inside the building because of the high humidity in Tahlequah. “Eastern Oklahoma is a very humid place. Humidity is the bane of our existence out here,” Roush said. He knew that the outdoor conditions in this area – 101° dry bulb, 80° wet bulb and 40% relative humidity – meant the project would need to use energy recovery ventilators in order to meet all code requirements while maintaining a comfortable building. More specifically, Roush wanted to use energy recovery units that utilized desiccant wheel technology because of the superior humidity control that desiccant wheel units provide.

In addition to considering the hot humid summer months, Roush knew the ERV system would provide energy savings in the winter months as well because Oklahoma can experience really cold weather. Without using an ERV in this system, supplemental heaters would need to be installed to raise the leaving air temperature to the desired set point during low ambient conditions. Choosing to include ERVs resulted in cost savings in two ways. First by avoiding the initial cost of purchasing and installing the supplemental heaters, and then the on going cost savings associated with not having to use the heaters.

BACKGROUND

Owners of the Tahlequah City Hospital decided to build a new Medical Office Building in Tahlequah, Oklahoma. They wanted to use a variable refrigerant system for the four-story building (43,000 sq.ft.) but they knew the VRV system would need to be complemented with an outdoor air delivery system. Flynt & Kallenberger Consulting Engineers of Oklahoma designed the HVAC system and included Energy Recovery Ventilators (ERV) that work wellfor both summer and winter operation.

Limited Space

Limited Space

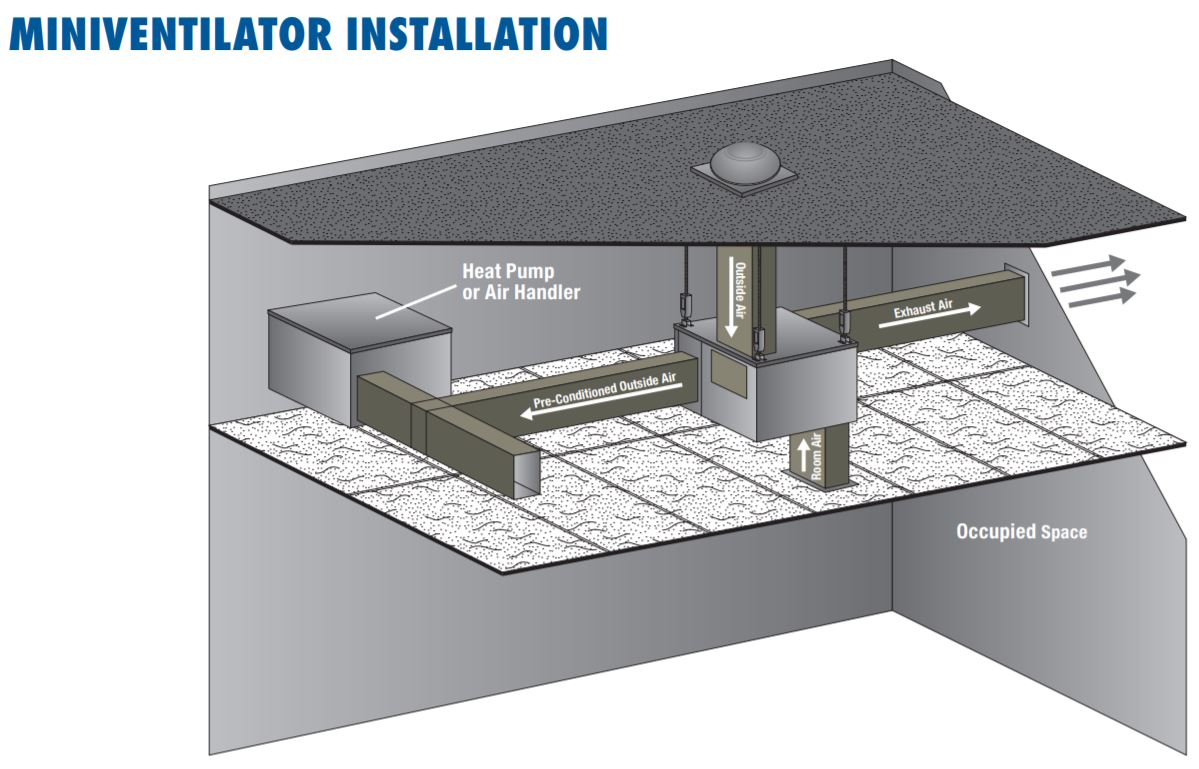

While reviewing ERV product lines used in previous projects, the engineer realized the building’s design and construction might not have the physical space available to include the necessary ERV’s into the building. However, during the design phase of this project, Chad Smith of Airetech Corporation contacted the engineer about a new Ruskin product, the MiniVentilator. Ruskin’s new low profile ERV would bring in the necessary outside air needed to meet ASHRAE Standard 62 without using too much precious space. Ruskin’s MV Series was the solution to overcome the issues of limited space while providing superior humidity control.

Final Decision

Using the flexibility of Ruskin’s new product, the four-story project was designed with two MiniVentilators per floor. The tempered air from the ERV’s was tied to the various incoming air ducts with balancing dampers. The design allows for a significant amount of humidity control and lowers the temperature of the incoming air stream, which will help reduce the stress on the cooling system.

GOOD FIT ALL AROUND

Using Energy Recovery Ventilators in the new Tahlequah Medical Office Building will provide consistent, comfortable air as well as dramatic energy savings for the owners over a building that did not utilize ERV’s in its HVAC system. Engineers now have a product available to use when space is a limited commodity in a building’s design. The flexibility of Ruskin’s MiniVentilator can be utilized in future designs when energy recovery is beneficial.

Learn more about the MV 750 MiniVentilator ERV

For over 50 years Ruskin has manufactured leading edge dampers and louvers. To learn more about our complete line of Ruskin products, or to locate the Ruskin representative nearest you, visit our website at www.ruskin.com or call us at (816) 761-7476.

Currently rated 0.0 by 0 people

Comments are closed for this post, but if you have spotted an error or have additional info that you think should be in this post, feel free to contact us.